It is more important than ever to have a clean and safe environment in the modern world. The bacterial filter is a crucial instrument for accomplishing this. Advanced tools called bacterial filters are made to capture and eliminate dangerous germs from a variety of situations, such as industrial, personal, and medical ones. This article explores the science underlying bacterial filters and shows why they are essential for maintaining your health.

What Are Bacterial Filters?

Bacterial filters are specialized filtration devices engineered to capture and eliminate bacteria from air, liquids, and gases. They are commonly used in medical settings to ensure sterile conditions, in industrial applications to maintain product purity, and in personal protective equipment to enhance individual safety. These filters operate based on advanced filtration technologies that ensure high efficiency and reliability.

How Do Bacterial Filters Work?

The primary mechanism of bacterial filters is based on physical filtration and, in some cases, chemical processes. Here’s a breakdown of how these filters work:

1. Physical Filtration:

• Mechanical Sieve: Bacterial filters often utilize a mechanical sieve to physically block and trap bacteria. This sieve consists of a porous membrane with holes smaller than the bacteria, ensuring that microorganisms are captured while allowing clean air or liquid to pass through.

• Electrostatic Attraction: Some filters use electrostatic forces to attract and retain bacteria. The filter material is charged to create an electrostatic field that draws bacteria towards the filter surface, where they are trapped.

2. Chemical Filtration:

• Adsorption: Certain bacterial filters incorporate adsorption materials, such as activated carbon, which chemically bind to and remove bacteria and other contaminants. This process helps in neutralizing harmful substances and improving the overall effectiveness of the filter.

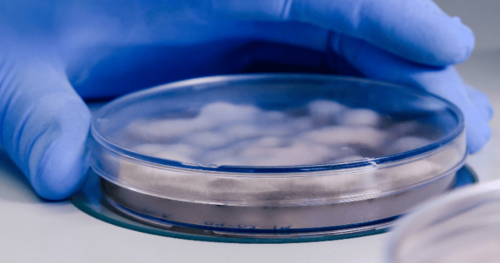

Types of Bacterial Filters

1. Air Filters: Used in HVAC systems and respirators, these filters remove airborne bacteria, improving indoor air quality and preventing respiratory infections.

2. Liquid Filters: Found in medical devices and laboratory equipment, these filters ensure that liquids are free from bacterial contamination, safeguarding patient health and ensuring accurate experimental results.

3. Gas Filters: Used in various industrial processes, these filters remove bacteria from gases, preventing contamination of products and ensuring safe operational environments.

Benefits of Bacterial Filters

• Enhanced Safety: By removing harmful bacteria, these filters help prevent infections and ensure a safe environment in healthcare settings, industrial processes, and everyday use.

• Improved Product Quality: In industries such as pharmaceuticals and food processing, bacterial filters contribute to the production of high-quality, uncontaminated products.

• Reliable Performance: With advanced filtration technologies, bacterial filters offer high efficiency and long-lasting protection against microbial threats.

Maintenance and Care

To ensure optimal performance, bacterial filters require regular maintenance. This includes cleaning or replacing the filter elements as recommended by the manufacturer. Proper care helps in maintaining the filter’s effectiveness and extending its lifespan.

Conclusion

The use of bacterial filters is essential in today’s health and safety procedures. You may recognise the value of these filters in preserving a healthy environment and safeguarding your health by being aware of the science underlying them and their many uses. Bacterial filters are a dependable way to counteract microbiological hazards and improve general safety, whether they are utilised in industrial, medicinal, or residential contexts.