In microbiology, microbial count plates are crucial instruments for measuring and examining the existence of microorganisms in diverse materials. The precision and dependability of the results depend heavily on how these plates are handled and stored. This thorough tutorial examines the ideal methods for managing and preserving microbiological count plates, with an emphasis on the premium goods supplied by GVS Malaysia.

Handling Microbial Count Plates

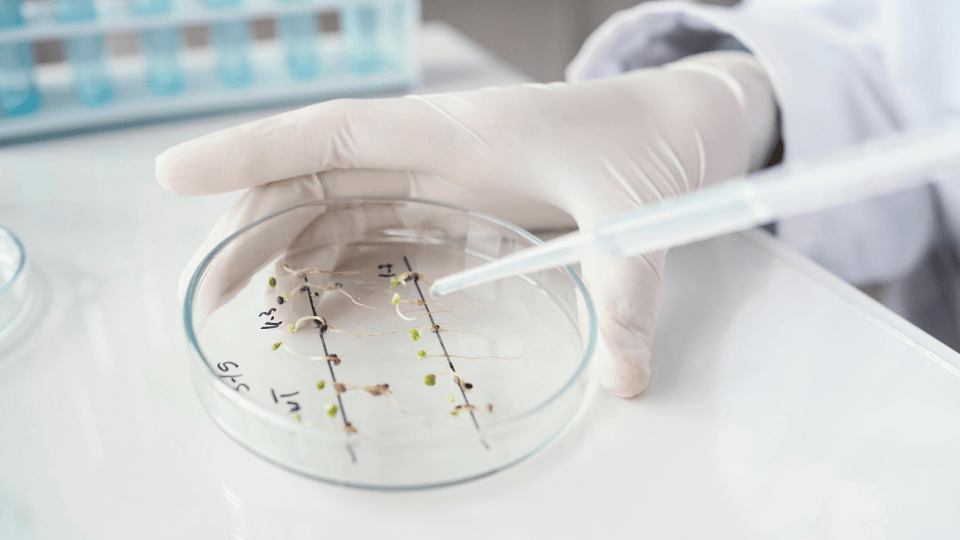

- Aseptic Technique: Always use aseptic techniques when handling microbial count plates to prevent contamination. This involves using sterilized tools and wearing gloves to handle the plates. Work within a laminar flow cabinet if possible, to maintain a sterile environment.

- Minimize Exposure: Keep the microbial count plates covered or enclosed as much as possible. Expose the media only during the actual application of the sample to prevent airborne contaminants from settling on the surface.

- Correct Labeling: Properly label each plate with relevant information such as the date, type of medium, and sample identifier. This helps in tracking and reduces errors during analysis.

- Use Fresh Plates: Always use plates that are within their expiry date. Over time, the nutrient quality of the medium can deteriorate, which might affect the growth and viability of the microbes.

Storing Microbial Count Plates

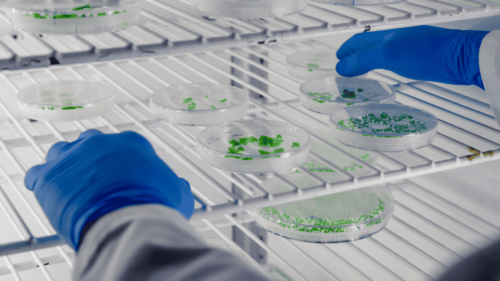

- Temperature Control: Store microbial count plates in a refrigerator at 2-8°C. This temperature range helps preserve the integrity of the growth medium and prevents the proliferation of contaminants that might be present.

- Inverted Storage: Store plates in an inverted position (i.e., the agar side up). This prevents condensation from accumulating on the agar surface, which can cause bacterial colonies to spread or merge, leading to inaccurate counts.

- Avoid Light Exposure: Store the plates in a dark place or cover them with a light-obstructive material. Some microorganisms are light-sensitive, and exposure to light can either kill them or trigger unwanted biological processes.

- Keep Them Sealed: If not used immediately, keep the plates sealed in their original packaging or in airtight containers to prevent exposure to the environment and to maintain humidity levels that are conducive for microbial growth.

Before Use

- Acclimatization: Before use, allow the plates to acclimate to room temperature for at least 30 minutes. This helps avoid condensation, which can interfere with sample application and microbial growth.

- Inspection Before Use: Inspect each plate for signs of contamination, dryness, or cracks in the medium. Do not use plates that show any of these signs as they can lead to erroneous results.

Conclusion

Accurate and trustworthy microbiological analyses depend on the proper handling and storage of microbial count plates. Labs can guarantee the accuracy of their results and the integrity of their samples by adhering to these best practices. High-quality microbiological count plates are offered by GVS Malaysia. When used and stored correctly, these plates can be extremely useful in the environmental monitoring, food safety, and healthcare industries.