In the pharmaceutical manufacturing industry, guaranteeing product safety and regulatory compliance is critical. Microbial contamination poses a substantial risk to product quality and patient safety. Microbial count plates are an important tool for monitoring and regulating microbial populations. GVS Malaysia is in the forefront of providing improved microbial count plates to improve pharmaceutical manufacturing safety.

The Importance of Microbial Testing in Pharmaceutical Manufacturing

Microbial testing is a fundamental aspect of the quality control process in pharmaceutical production. It helps manufacturers ensure that their products are free from harmful bacteria, yeast, and mold. The use of microbial count plates, provided by GVS Malaysia, allows for the rapid detection and quantification of microorganisms in raw materials, in-process samples, and finished products.

How Microbial Count Plates Work

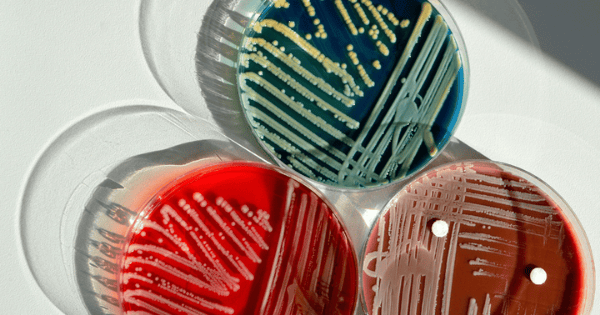

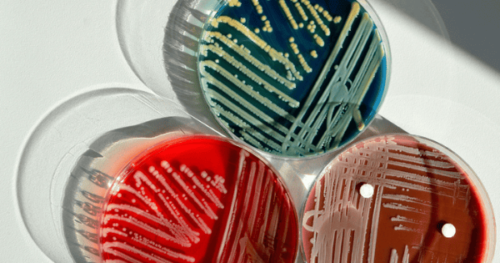

Microbial count plates are ready-to-use diagnostic tools that contain a growth medium and an indicator. When a sample is applied to the plate, microorganisms grow and form colonies that can be counted, providing a quantitative measure of contamination. GVS Malaysia offers a variety of microbial count plates tailored to detect specific types of microorganisms, including those most relevant to pharmaceutical contexts.

Advantages of Using GVS Malaysia’s Microbial Count Plates

GVS Malaysia’s microbial count plates offer several advantages over traditional culturing methods:

- Speed: These plates reduce the time to result, allowing for quicker responses to contamination and faster batch release.

- Ease of Use: They are pre-prepared and require minimal setup, making them ideal for routine use in busy pharmaceutical environments.

- Accuracy: GVS Malaysia’s plates are designed to meet stringent industry standards, providing reliable and reproducible results.

- Cost-Effectiveness: By streamlining the microbial testing process, these plates can reduce overall laboratory costs.

Applications in Pharmaceutical Manufacturing

GVS Malaysia’s microbial count plates are used across various stages of pharmaceutical production:

- Raw Material Testing: Ensuring that incoming materials meet quality specifications.

- In-Process Testing: Monitoring microbial levels during production to ensure that processes remain under control.

- Finished Product Testing: Verifying that final products are safe for market release.

Meeting Regulatory Standards

The use of microbial count plates helps pharmaceutical manufacturers comply with international regulatory standards, such as those set by the FDA and EMA. GVS Malaysia ensures that its microbial count plates are up to date with regulatory requirements, providing clients with confidence in their compliance and product safety.

Conclusion

Microbial count plates from GVS Malaysia are an important instrument for improving pharmaceutical manufacturing safety. They contribute to the safety of pharmaceutical products by allowing for rapid, accurate, and low-cost microbiological testing. GVS Malaysia’s dedication to quality and innovation in microbiological testing continues to help the pharmaceutical industry satisfy safety and regulatory requirements.