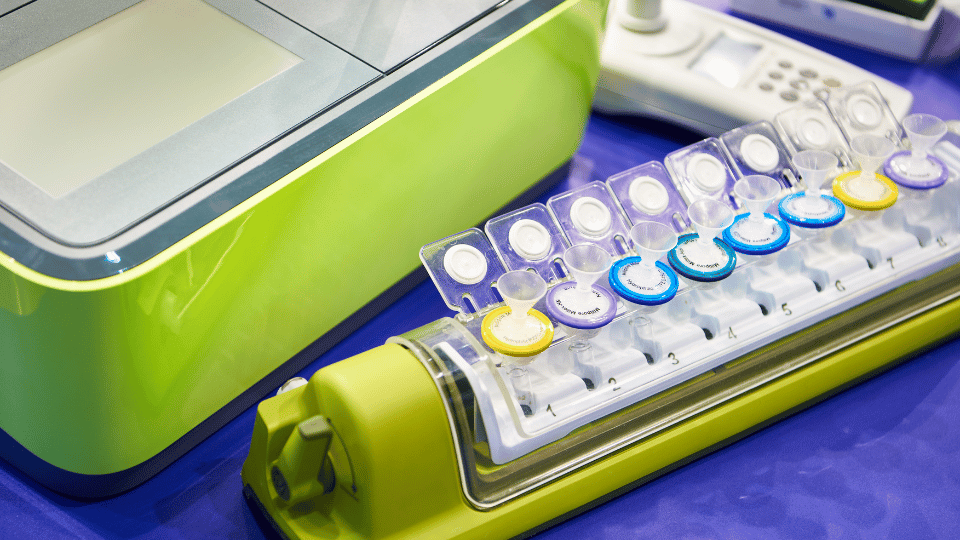

Syringe filters, which are used to remove particles and impurities from liquids before analysis or usage, are crucial instruments in laboratory environments. In order to provide accurate results and prolong the equipment’s life, proper usage and maintenance of these filters are essential. You will be guided through the process of properly using and maintaining syringe filters by this in-depth tutorial.

What is a Syringe Filter?

A syringe filter is a small, disposable filter that attaches to the end of a syringe. It is designed to remove particulates, microorganisms, and other contaminants from liquids. Syringe filters come in various pore sizes and materials to suit different filtration needs, including applications in research, pharmaceuticals, and biotechnology.

How to Properly Use Syringe Filters

1. Select the Appropriate Filter:

• Pore Size: Choose a pore size suitable for your application. Common pore sizes range from 0.2 µm for sterilization to 0.45 µm for particulate removal.

• Filter Material: Select a filter material compatible with your sample. Materials like nylon, PVDF, and PTFE are used based on chemical compatibility and sample type.

2. Prepare the Syringe:

• Cleanliness: Ensure the syringe is clean and free from any contaminants. Use sterile syringes for biological samples to avoid contamination.

• Assembly: Attach the syringe filter to the syringe firmly. Make sure the filter is oriented correctly; typically, the inlet is larger than the outlet.

3. Filter the Sample:

• Slow and Steady: Draw the liquid sample into the syringe and slowly push it through the filter. Avoid rapid pushing, which can lead to filter clogging or rupture.

• Volume Limit: Do not exceed the maximum volume capacity of the filter. Check the manufacturer’s specifications to avoid overloading.

4. Dispose of the Filter Properly:

• Post-Use: After filtering, detach the filter and dispose of it according to your lab’s waste disposal protocols. Syringe filters are generally single-use and should not be reused.

How to Maintain Syringe Filters

1. Avoid Overuse:

• Single Use: Syringe filters are typically designed for single-use only. Reusing filters can lead to contamination and compromised results.

2. Proper Storage:

• Dry and Cool: Store syringe filters in a clean, dry, and cool environment to prevent damage or degradation. Avoid exposure to extreme temperatures or humidity.

3. Check for Damage:

• Inspect Before Use: Always check the filter for any signs of damage, such as cracks or leaks, before use. A damaged filter can compromise your results and lead to sample contamination.

4. Handle with Care:

• Avoid Contamination: Handle filters with clean, sterile gloves to avoid introducing contaminants. Do not touch the filter membrane directly.

5. Regular Training:

• Staff Training: Ensure that laboratory staff are trained in the proper use and maintenance of syringe filters to maintain high standards of accuracy and safety.

Conclusion

Accurate and dependable results in laboratory work depend on the proper use and upkeep of syringe filters. You can guarantee the efficiency of your filtering process and increase the lifespan of your equipment by choosing the appropriate filter, managing it carefully, and adhering to precise disposal and storage procedures. Following these recommendations promotes the success of your research or analytical work overall and helps preserve the integrity of your samples.