Choosing the appropriate syringe filter is an essential stage in the sample preparation process, which is crucial in laboratory settings where sample purity is crucial. Syringe filters improve test result reproducibility in addition to safeguarding delicate analytical equipment. Each of the many syringe filters that GVS Malaysia offers is appropriate for a certain kind of sample or solvent. Choosing the right syringe filter for your lab needs is made easier with the help of this guide.

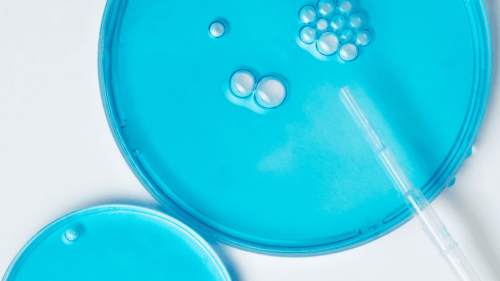

What is a Syringe Filter?

A syringe filter is a single-use filter cartridge that attaches to the end of a syringe and is used to remove particulates from a liquid prior to analysis. By filtering out unwanted materials, syringe filters prevent damage to instrumentation and interference in the analytical results. They come in various diameters and pore sizes and are made from different materials to be compatible with specific chemical solvents and applications.

Factors to Consider When Selecting a Syringe Filter

- Membrane Material:

- Polytetrafluoroethylene (PTFE): Ideal for organic solvents and strong acids due to its strong chemical resistance.

- Nylon: Versatile and suitable for both aqueous and organic solvents, making it a popular choice for general laboratory use.

- Polyvinylidene fluoride (PVDF): Preferred for protein recovery applications as it has low protein binding.

- Cellulose Acetate: Best for sensitive biological samples as it promotes low protein binding and is hydrophilic.

- Pore Size:

- The pore size selection depends on the required filtration level. Common sizes include 0.22 µm for sterile applications and 0.45 µm for clarification of particulates.

- Diameter:

- Syringe filter diameter should be chosen based on the volume of the sample that needs to be filtered. Smaller diameters are suitable for samples under 10 mL, while larger diameters are needed for volumes up to 100 mL to reduce pressure build-up and prevent filter blowout.

- Sample Compatibility:

- Ensure the filter material is compatible with the sample being processed. For instance, PTFE is inert and broad-range, suitable for aggressive solvents, whereas Nylon is a more cost-effective option for less corrosive liquids.

Best Practices for Syringe Filter Use

- Pre-wetting the Filter: Some filters, particularly hydrophobic membranes like PTFE, should be pre-wet with alcohol before filtering aqueous solutions to prevent membrane blockage.

- Volume and Pressure: Avoid applying excessive pressure during filtration, which can cause the filter membrane to burst or the sample to pass through too quickly, reducing filtration efficacy.

- Sample Volume: Use a filter size appropriate for your sample volume to optimize flow rates and ensure complete filtration without wasting any sample.

Conclusion

Choosing the appropriate syringe filter is essential for both safeguarding lab equipment and achieving precise analytical results. Labs can improve their testing procedures by taking into account elements like sample compatibility, pore size, and membrane material. The wide selection of syringe filters offered by GVS Malaysia guarantees that you will discover the ideal fit for any application, upholding the highest standards of efficiency and purity in your laboratory work.